2000 toyota camry le repair manual

TOYOTA f ENGINE REPAIR MANUAL HƯỚNG dẫn sửa CHỮA ĐỘNG cơ f TOYOTA

Ngày tải lên: 28/03/2014, 09:19

TOYOTA CELICA 2000 SERVICE REPAIR MANUAL - HƯỚNG dẫn sửa CHỮA XE TOYOTA CELICA đời 2000

Ngày tải lên: 23/05/2014, 16:02

Toyota camry 2006 2011 body repair manual hướng dẫn sửa chữa thân xe toyota camry đời 2006 2011

Ngày tải lên: 24/05/2014, 13:18

TOYOTA 1HZ 1HD t 1990 REPAIR MANUAL HƯỚNG dẫn sửa CHỮA ĐỘNG cơ 1HZ 1HD t TOYOTA

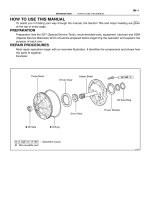

... IMPROPER ADJUSTMENT OF ACCELERATOR CABLE With accelerator pedal released, check that adjusting lever is in contact with idle speed adjusting screw. Also check if accelerator cable or linkage is catching on ... OUTLET (a) (1HD-T) Disconnect the water by-pass hose. (b) Remove the two nuts, water outlet and gasket. 7. REMOVE NOZZLE LEAKAGE PIPE (1PZand1HZ) (a) (1PZ) Remove the five union nuts, nozzle leakage ... task. TROUBLESHOOTING tables are included for each system to help you diagnose the problem and find the cause. The repair for each possible cause is referenced in the remedy column to quickly lead...

Ngày tải lên: 28/03/2014, 10:07

TOYOTA COROLLA 2ZZ GE ENGINE REPAIR MANUAL HƯỚNG dẫn sửa CHỮA ĐỘNG cơ 2ZZ GE TRÊN XE TOYOTA COROLLA

... also been prepared as relevant service manuals for the components and systems in this vehicles. Manual Name Pub. No. S COROLLA Repair Manual RM925E All information in this manual is based on the ... Clamp Clamp T rack 01 6 INTRODUCTION REPAIR INSTRUCTION FOR ENGINE REPAIR MANUAL (2ZZ GE) 2ZZ GE ENGINE REPAIR MANUAL (RM929E) (3) Never use any electric equipment like an electric motor or a working light ... USE THIS ENGINE REPAIR MANUAL (2ZZ-GE) 01 1 2ZZ GE ENGINE REPAIR MANUAL (RM929E) HOW TO USE THIS ENGINE REPAIR MANUAL (2ZZ GE) GENERAL INFORMATION 1. GENERAL DESCRIPTION (a) This manual is made...

Ngày tải lên: 28/03/2014, 10:16

Camry Repair Manual AIR CONDITION

... ECM. 6. DISCONNECT AIR INLET DAMPER CONTROL CABLE HINT: At the in time of installation, please refer to following item. After connection, inspect the air inlet control lever operation. (See page ... VISUALLY FOR LEAKAGE OF REFRIGER- ANT FROM SAFETY SEAL Using a gas leak detector, check for leakage of refrigerant. If there is any leakage, replace the compressor assembly. 5. CHECK FOR LEAKAGE OF ... bat- tery. Standard clearance: 0.5 ± 0.15 mm (0.020 ± 0.0059 in.) If the clearance is not within the standard clearance, adjust the clearance using shims to obtain the standard clearance. Shim thickness: 0.1...

Ngày tải lên: 28/04/2014, 12:52

Camry Repair Manual AUTOMATIC TRANSAXLE

... DateĂ: VEHICLE SPEED SENSOR ON–VEHICLE REPAIR 1. REMOVE AIR CLEANER ASSEMBLY 2. DISCONNECT VEHICLE SPEED SENSOR CONNEC- TOR 3. REMOVE VEHICLE SPEED SENSOR ASSEMBLY (a) Remove the bolt and vehicle speed ... THROTTLE CABLE (a) Disconnect the throttle cable. (b) Remove the valve body. 10. REMOVE 2ND BRAKE APPLY GASKET 11. REMOVE SHIFT SOLENOID VALVE NO.1 AND NO.2 (a) Remove the 2 bolts and shift solenoid ... Q10051 AX03A–01 AX–10 –AUTOMATIC TRANSAXLE (A140E) SHIFT SOLENOID VALVE SL 1903A uthorĂ: DateĂ: SHIFT SOLENOID VALVE SL ON–VEHICLE REPAIR 1. REMOVE PARK/NEUTRAL POSITION SWITCH (See page AX–4) 2. DISCONNECT SHIFT SOLENOID VALVE...

Ngày tải lên: 28/04/2014, 12:53

Camry Repair Manual AUTOMATIC TRANSAXLE MANUAL

... fluid for the automatic transaxle: DEXRON đ @@@@@: [g 2] GENERAL CLEANING NOTES: 1. All disassembled parts should be washed clean and any fluid passages and holes blown through with compressed ... union and elbow. 3. REMOVE SL SOLENOID (a) Disconnect the connector. (b) Remove the 2 bolts and SL solenoid. 4. REMOVE THROTTLE CABLE RETAINING PLATE 5. REMOVE SOLENOID WIRE RETAINING BOLT 6. REMOVE ... Clean the battery terminal posts and cable terminals with a clean shop rag. Do not scrape them with a file or other abrasive objects. (e) Install the cable terminal to the battery post with the nut...

Ngày tải lên: 28/04/2014, 13:01

Camry Repair Manual BODY ELECTRICAL

... SYSTEM 2222AuthorĂ: DateĂ: PROBLEM SYMPTOMS TABLE POWER OUTLET Symptom Suspect Area See page Electric power source cannot be taken out of the power outlet 11.Battery 12.POWER OUTLET Fuse (I/P J/B No.1) 13.Wire ... BE0A1–03 N20688 Power Outlet Instrument Panel J/B No.1 D PWR OUTLET Fuse BE–12 –BODY ELECTRICAL POWER OUTLET 2232AuthorĂ: DateĂ: POWER OUTLET LOCATION Z19055 PKB Switch Seat Belt Buckle Switch Door Courtesy ... Switch D Wiper and Washer Switch Spiral Cable –BODY ELECTRICAL HEADLIGHT AND TAILLIGHT SYSTEM BE–23 2243AuthorĂ: DateĂ: COMPONENTS BE–8 –BODY ELECTRICAL BODY ELECTRICAL SYSTEM 2228AuthorĂ: DateĂ: Shift...

Ngày tải lên: 28/04/2014, 13:03

Camry Repair Manual BODY ELECTRICAL BODY

... positive (+) lead from the battery to terminal 16 and the negative (–) lead to terminal 2. (d) Connect the positive (+) lead from the voltmeter to termi- nal 7 and the negative (–) lead to terminal ... lock manual switch OFF or UNLOCK No continuity A16 – Ground Door lock manual switch LOCK Continuity A17 – Ground Door lock manual switch OFF or LOCK No continuity A17 – Ground Door lock manual ... 173 2. INSPECT VEHICLE SPEED SENSOR OPERATION (a) Connect the positive (+) lead from the battery to terminal 1 and negative (–) lead to terminal 2. (b) Connect the positive (+) lead from the tester...

Ngày tải lên: 28/04/2014, 13:07

Camry Repair Manual BRAKE

... Cylinder Boot Adjuster SCup Piston SC–washer Inspection Hole Plug Pin Front Shoe Cup Shoe Hold–down Spring Adjuster Rear Shoe Anchor Spring Parking Brake Lever Automatic Adjusting Lever E–ring Adjusting Lever Spring Bleeder Plug High ... Nut BR0AD–03 BR–8 –BRAKE PARKING BRAKE LEVER 2031AuthorĂ: DateĂ: PARKING BRAKE LEVER ON–VEHICLE INSPECTION 1. CHECK THAT PARKING BRAKE LEVER TRAVEL Pull the parking brake lever all the way up, and count ... pulling straight out, not at an angle. NOTICE: S If pulled out and installed at an angle, there is a possi- bility that the cylinder bore could be damaged. S At the time of reassembly, please refer to the follow- ing...

Ngày tải lên: 28/04/2014, 13:08

Camry Repair Manual CHARGING

... caliper, measure the exposed brush length. Standard exposed length: 10.5 mm (0.413 in.) Minimum exposed length: 1.5 mm (0.059 in.) If the exposed length is less than minimum, replace the brushes and ... calipers, measure the exposed brush length. Standard exposed length: 10.5 mm (0.413 in.) Minimum exposed length: 1.5 mm (0.059 in.) If the exposed length is less than minimum, replace the brush holder ... disconnect the battery while the engine is running. 1. CHECK BATTERY ELECTROLYTE LEVEL Check the electrolyte quantity of each cell. (1) Maintenance–Free Battery: If under the lower level, replace the...

Ngày tải lên: 28/04/2014, 13:08

Camry Repair Manual CLUTCH

... freeplay. z Bleed the clutch line. z Inspect the clutch cover and disc. CL034–01 –CLUTCH TROUBLESHOOTING CL–1 1780AuthorĂ: DateĂ: TROUBLESHOOTING PROBLEM SYMPTOMS TABLE Use the table below to ... 08887–01706 (100 g). 4. INSTALL RELEASE BEARING AND FORK TO TRANS- AXLE Install the bearing to the release fork, and then install them to the transaxle. 5. INSTALL TRANSAXLE TO ENGINE (See page E153 ... CLUTCH RELEASE POINT (a) Pull the parking brake lever and install wheel stopper. (b) Start the engine and idle the engine. (c) Without depressing the clutch pedal, slowly shift the shift lever into...

Ngày tải lên: 28/04/2014, 13:08

Camry Repair Manual COOLANT

... O–ring. 3. ASSEMBLE SST SST 09230–01010 (a) Install the claw to the overhaul handle, inserting it in the hole in part ”A” as shown in the diagram. (b) While gripping the handle, adjust the stopper ... Timing Belt Cover Crankshaft Pulley No.2 Idler Pulley Generator Drive Belt Adjusting Bar Wire Clamp Crankshaft Position Sensor Connector * Gasket No.1 Idler Pulley Tension Spring z O–Ring Water ... Engine Mounting Bracket Crankshaft Pulley Gasket Engine Wire Protector RH Camshaft Timing Pulley No.2 Idler Pulley Dust Boot Timing Belt Tensioner z Non–reusable part *For use with SST No.1 Timing...

Ngày tải lên: 28/04/2014, 13:10

Camry Repair Manual DIAGNOSTICS

... scan tool or TOYOTA hand–held tester to DLC3 on the vehicle. CHECK: Use the CURRENT DATA to check the idle speed. OK: Idle speed: 650 ∼ 750 rpm NG Proceed to problem symptoms table on page DI–28. OK ... book.) DTCs include SAE controlled codes and manufac- turer controlled codes. SAE controlled codes must be set as prescribed by the SAE, while manufactur- er controlled codes can be set freely by ... the air–fuel ratio lean or rich, etc. at the time of the malfunction. D Priorities for troubleshooting: If troubleshooting priorities for multiple DTCs are given in the applicable DTC chart, these...

Ngày tải lên: 28/04/2014, 13:17

Camry Repair Manual EMISSION CONTROL

... vacuum does not decrease when the air inlet port is closed, and check that the vacuum decreases when the air inlet port is released. (5) While holding the air inlet port closed, apply vacuum (3.43 ... vacuum does not decrease when the air inlet port is closed, and check that the vacuum decreases when the air inlet port is released. (5) While holding the air inlet port closed, apply vacuum (3.43 ... canister. 7. CHECK AIR INLET LINE (a) Disconnect the air inlet line hose from the charcoal canis- ter. (b) Check that there is ventilation in the air inlet line. (c) Reconnect the air inlet line hose to...

Ngày tải lên: 28/04/2014, 13:17

Camry Repair Manual ENGINE MECHANICAL

... belt. 2. INSPECT IDLER PULLEYS (a) Visually check the seal portion of the idler pulley for oil leakage. If leakage is found, replace the idler pulley. (b) Check that the idler pulley turns smoothly. If ... and crankshaft timing pulley. 17. REMOVE NO.1 IDLER PULLEY AND TENSION SPRING Remove the bolt, pulley and tension spring. 18. REMOVE NO.2 IDLER PULLEY Remove the bolt and pulley. A02591 S05588 SST SST S05592 SST SST Fulcrum Length S05587 Turn –ENGINE ... FROM CAMSHAFT TIM- ING PULLEY (See page EM–17) 18. REMOVE CAMSHAFT TIMING PULLEY (See page EM–17) 19. REMOVE NO.1 IDLER PULLEY AND TENSION SPRING Remove the bolt, pulley and tension spring. 20....

Ngày tải lên: 28/04/2014, 13:24

Bạn có muốn tìm thêm với từ khóa: