safety precautions for gas shielded arc welding

Tài liệu Welders Handbook For Gas Shielded Arc Welding, Oxy Fuel Cutting & Plasma Cutting pptx

... CONTENTS Introduction Fusion welding Why use welding? Arc welding processes Welding terms MIG/MAG welding TIG welding 10 Plasma welding 17 Welding sheet 18 Welding plate 20 Welding pipes 22 Defects ... copper) See pages 2628 for choosing the right gas Tungsten inert gas welding Principles Tungsten inert gas shielded welding is usually called TIG welding It uses an arc between a tungsten electrode ... welds 24 The right gas: MIG/MAG welding 26 TIG welding 29 Welding data: MIG/MAG welding 30 Flux cored electrodes 33 TIG welding 34 Oxy-fuel gas cutting 37 Plasma cutting 44 Safety always 46 Conversion...

Ngày tải lên: 25/02/2014, 10:20

Guidelines For Gas Metal Arc Welding (GMAW)_1 doc

... Unregistered Version ARC WELDING (GMAW) Gas Metal Arc Welding (GMAW) is a welding process which joins metals by heating the metals to their melting point with an electric arc The arc is between a ... the hazard The safety information given below is only a summary of the more complete safety information found in the Safety Standards listed in Section 1-5 Read and follow all Safety Standards ... and/or use local forced ventilation at the arc to remove welding fumes and gases D If ventilation is poor, wear an approved air-supplied respirator D Read and understand the Material Safety Data Sheets...

Ngày tải lên: 20/06/2014, 17:20

Processes MIG (GMAW) WeldingGuidelines For Gas Metal Arc Welding pot

... surface before welding Insufficient shielding gas at welding Increase flow of shielding gas at regulator/flowmeter and/or prevent drafts near welding arc arc Dirty welding wire Use clean, dry welding ... doctor before welding or going near welding operations If cleared by your doctor, then following the above procedures is recommended SECTION − GAS METAL ARC WELDING (GMAW) Gas Metal Arc Welding ... metal solidifies Wrong gas Use welding grade shielding gas; change to different gas Dirty welding wire Use clean, dry welding wire Eliminate pick up of oil or lubricant on welding wire from feeder...

Ngày tải lên: 27/06/2014, 17:20

Guidelines To Gas Tungsten Arc Welding (GTAW)_2 docx

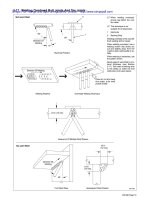

... PDF Merge and − GUIDELINES FOR GTAW WELDING (TIG) 6-1 Lift -Arc And HF TIG Start Procedures Lift -Arc Start When Lift-Arct button light is On, start arc as follows: Lift -Arc Start Method “Touch” ... http://www.simpopdf.com 5-1 TIG Shielding Gases See page 38 in Gas Tungsten Welding book, available through MILLER Electric, for more information about shielding gases 5-2 Argon vs Helium Page 14 5-3 ... that, for AC welding, operators should sharpen the tungsten as if they are welding in the DC mode This is true for all advanced TIG machines, and especially for inverter because it optimizes performance...

Ngày tải lên: 20/06/2014, 17:20

Guidelines To Gas Tungsten Arc Welding (GTAW) pot

... See Safety Precautions at beginning of welding power source Owner’s Manual swarn6.2* 8/92 for basic welding safety information This booklet is a guide to TIG welding basics More detailed information ... that, for AC welding, operators should sharpen the tungsten as if they are welding in the DC mode This is true for all advanced TIG machines, and especially for inverter because it optimizes performance ... Tungsten Shape For AC Sine Wave & Conventional Squarewave 4-6 Tungsten Shape For Inverter AC & DC Page 13 SECTION − TIG SHIELDING GASES 5-1 TIG Shielding Gases See page 38 in Gas Tungsten Welding book,...

Ngày tải lên: 27/06/2014, 05:20

Guidelines To Gas Tungsten Arc Welding (GTAW) WARNINGARC WELDING ppt

... See Safety Precautions at beginning of welding power source Owner’s Manual swarn6.2* 8/92 for basic welding safety information This booklet is a guide to TIG welding basics More detailed information ... that, for AC welding, operators should sharpen the tungsten as if they are welding in the DC mode This is true for all advanced TIG machines, and especially for inverter because it optimizes performance ... Tungsten Shape For AC Sine Wave & Conventional Squarewave 4-6 Tungsten Shape For Inverter AC & DC Page 13 SECTION − TIG SHIELDING GASES 5-1 TIG Shielding Gases See page 38 in Gas Tungsten Welding book,...

Ngày tải lên: 27/06/2014, 17:20

Guidelines For Shielded Metal Arc Welding (SMAW)_3 pptx

... SECTION − WELDING TROUBLESHOOTING 4-1 Porosity Porosity − small cavities or holes resulting from gas pockets in weld metal Possible Causes Corrective Actions Arc length too long Reduce arc length ... cool to solid form near weld bead Possible Causes Amperage too high for electrode Corrective Actions Decrease amperage or select larger electrode Arc length too long or voltage Reduce arc length ... amperage Improper welding technique Place stringer bead in proper location(s) at joint during welding Adjust work angle or widen groove to access bottom during welding Momentarily hold arc on groove...

Ngày tải lên: 20/06/2014, 17:20

SMAW (Pro Series): Welding Guidelines For Shielded Metal Arc Welding pot

... doctor before welding or going near welding operations If cleared by your doctor, then following the above procedures is recommended SECTION − PRINCIPLES OF SHIELDED METAL ARC WELDING (SMAW) Shielded ... the hazard The safety information given below is only a summary of the more complete safety information found in the Safety Standards listed in Section 1-5 Read and follow all Safety Standards ... Information SECTION − PRINCIPLES OF SHIELDED METAL ARC WELDING (SMAW) SECTION − SHIELDED METAL ARC...

Ngày tải lên: 27/06/2014, 05:20

ProcessesStick (SMAW) WeldingGuidelines For Shielded Metal Arc Welding potx

... doctor before welding or going near welding operations If cleared by your doctor, then following the above procedures is recommended SECTION − PRINCIPLES OF SHIELDED METAL ARC WELDING (SMAW) Shielded ... the hazard The safety information given below is only a summary of the more complete safety information found in the Safety Standards listed in Section 1-5 Read and follow all Safety Standards ... Information SECTION − PRINCIPLES OF SHIELDED METAL ARC WELDING (SMAW) SECTION − SHIELDED METAL ARC...

Ngày tải lên: 27/06/2014, 08:20

Tài liệu A SAFETY GUIDE FOR SMALL OFFSHORE FISHING BOATS ppt

... cavitation and surface erosion Therefore, a preliminary check is advisable before consulting a propeller designer or naval architect for further assistance A simple method for making a first estimate ... changes in a vessel's performance or be able to compare the performance of one vessel with another The collection of simple performance information provides the basis for a choice of optimum speed ... speed is necessary for safety reasons (e.g to avoid bad weather) or when the penalty price paid for increased fuel consumption is likely to be compensated by better market prices for the catch 7...

Ngày tải lên: 12/12/2013, 16:16

Tài liệu PERFORMANCE AND SAFETY STUDIES FOR MULTI-APPLICATION, SMALL, LIGHT WATER REACTOR ( MASLWR) pptx

... Transient Performance As noted, the transient performance characterization was performed with an input file containing an early steam generator tube bundle configuration, and therefore the following ... would provide a path for cooling the primary system Such an effective heat transfer mechanism may obviate the need for a sump makeup valve Therefore, a calculation was performed to evaluate the ... temperature below 311K (100 F) For the most severe postulated accident, the volume of water in the cavity provides a passive ultimate heat sink for or more days, permitting time for restoration of the...

Ngày tải lên: 16/01/2014, 22:20

Tài liệu Environmental, Health and Safety Guidelines for Large Volume Petroleum-based Organic Chemicals Manufacturing pptx

... stream to the furnace gas system for recovery into fuel gas or to flare; • Adopting closed loop systems for sampling; The normally accepted material loss for good operating performance is around ... United States 2.2 Occupational Health and Safety Performance Occupational Health and Safety Guidelines National Institute for Occupational Health and Safety (NIOSH),30 Permissible Exposure Limits ... carbon (only for methanol storage vents), absorption in water recycled to the process, or connection Formaldehyde to the suction of the process air blower (only for Primary sources of formaldehyde...

Ngày tải lên: 14/02/2014, 03:20

Tài liệu Environmental, Health, and Safety Guidelines for Poultry Production pptx

... poultry carcass disposal is available in Carcass Disposal: A Comprehensive Review, Kansas State University (2004) available at http://fss.k-state.edu/research/books/carcassdisp.html; Guidelines for ... incinerations facilities are available in the EHS Guidelines for Waste Management Facilities 15 Many countries forbid burial of carcasses More information on the treatment of dead animals can be found ... http://www.aphis.usda.gov/animal_health/index.shtml 25 For further information on culling and disposal of carcasses, in addition to animal health issues, see Carcass Disposal: A Comprehensive Review, Kansas...

Ngày tải lên: 21/02/2014, 01:20

Tài liệu Commodity Specific Food Safety Guidelines for the Lettuce and Leafy Greens Supply Chain ppt

... (www.uffva.org/news/fccbest8_3a.pdf) • www.uffva.org 24 Websites Gateway to Government Food Safety Information www.foodsafety.gov/ Partnership for Food Safety Information Fight BAC! www.fightbac.org Produce Education Handling ... Food Safety Management Guide: A Model Program for Raw Ready-To-Eat Fresh-cut Produce (www.fmi.org/forms/store/ProductFormPublic/search?action=1&Product_productNumber=2014) 11.AFDO Guidance for ... Guidance Information Required Reference Documents FDA Guide to Minimize Microbial Food Safety Hazards for Fresh Fruits and Vegetables (www.foodsafety.gov/~dms/prodguid.html) UFFVA Food Safety Auditing...

Ngày tải lên: 21/02/2014, 08:20

ARC WELDING ELECTRODE

... of the electrodes will not be uniform 03/12/14 ARC WELDING ELECTR 29 TEMPERATURE REGULATOR BAKING OVEN 03/12/14 ARC WELDING ELECTR 30 POTABLE OVEN 03/12/14 ARC WELDING ELECTR 31 When the electrodes ... STRIKING END CORE BARE END FOR GRIPPING D = COVERING DIA , d= CORE DIA 03/12/14 ARC WELDING ELECTR TYPES OF ELECTRODE Arc welding electrodes are classified in groups by American Welding Society (AWS ... ELECTRODES TESTING OF ELECTRODES 03/12/14 ARC WELDING ELECTR HISTORY OF ARC WELDING COATED ELECTRODE During first stage of work with metal arc welding a bare electrode was in use which was...

Ngày tải lên: 12/03/2014, 16:49

Synthesis and characterization of semiconducting nanowires for gas sensing

... nanostructured metal oxides for gas sensing applications His main activity regards synthesis and electrical characterization of metal oxides for gas sensing applications Presently, he is researcher at the ... obtained for an operating temperature of 400 ◦ C for both the samples Optical characterization Photoluminescence (PL) spectroscopy was performed over a wide temperature and wavelength range for the ... solid-state gas sensors with superior performance-NANOS4” STREP project no 001528 “Nanostructured semiconductors for chemical sensing” PRIN project 2004 “Quasi mono dimensional nanosensors for label...

Ngày tải lên: 16/03/2014, 15:25

aluminum-doped tio2 nano-powders for gas sensors

... 600–900 ◦ C [19] Since ionic radii for Al and Ti are close to each other (0.074 nm for Ti4+ and 0.0675 nm for Al3+ ) [20], Al can occupy a regular cation position, forming a substitutional solid ... meters, and for all of these tests, the total gas flow rate was fixed at 150 cm3 min−1 Air, pure nitrogen and CO gases were allowed to mix during their passage to the test setup Before electrical ... area for all calcination temperatures; however, a drop at wt.% Al is also seen The highest surface area of 25 m2 /g is observed for the pure TiO2 powders calcined at 700 ◦ C for h TEM images for...

Ngày tải lên: 19/03/2014, 16:47

comparative study of nanocrystalline sno2 materials for gas sensor application

... to form printable ink The ink was deposited on sensor microheater platform, dried for 15 at 150 ◦ C and annealed at 700 ◦ C for 15 to reach the stabilization of the material The sensor platforms ... of propane in synthetic air at 50% RH The gas concentrations and gas humidification were prepared with gas mixing system Environics 4000 at 20 ◦ C Before the measurements all sensors were stabilized ... 10 exposition to pure carrier gas (synthetic air, 50% RH) The sensor signal was defined as a ratio Rair /Rgas , where Rgas is the sensing layer resistance in target gas atmosphere and Rair is the...

Ngày tải lên: 19/03/2014, 16:47

Bạn có muốn tìm thêm với từ khóa:

- guidelines to gas tungsten arc welding

- safety precautions for welding and cutting containers that have held combustibles

- safety precautions for welding and cutting polyurethane foam filled assemblies

- cooled curved neck gas metal arc welding gun

- hàn tig gtaw gas tungsten arc welding

- gas metal arc weldingmig