cooled curved neck gas metal arc welding gun

Guidelines For Gas Metal Arc Welding (GMAW)_1 doc

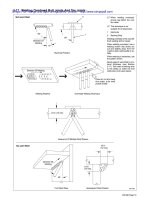

... Unregistered Version ARC WELDING (GMAW) Gas Metal Arc Welding (GMAW) is a welding process which joins metals by heating the metals to their melting point with an electric arc The arc is between a ... Supply of Electrode Wire S Welding Gun - delivers electrode wire and shielding gas to the weld puddle S Shielding Gas Cylinder - provides a supply of shielding gas to the arc 154 557 Page 2-1 Typical ... (CV) Welding Power Source Weld Cable To Feeder Ground Cable To Workpiece Workpiece Voltage-Sensing Clamp Welding Gun Gun Trigger Receptacle Voltage-Sensing Wire Feeder Gas Hose 10 Shielding Gas...

Ngày tải lên: 20/06/2014, 17:20

Processes MIG (GMAW) WeldingGuidelines For Gas Metal Arc Welding pot

... doctor before welding or going near welding operations If cleared by your doctor, then following the above procedures is recommended SECTION − GAS METAL ARC WELDING (GMAW) Gas Metal Arc Welding (GMAW) ... before welding Insufficient shielding gas at welding Increase flow of shielding gas at regulator/flowmeter and/or prevent drafts near welding arc arc Dirty welding wire Use clean, dry welding ... until molten metal solidifies Wrong gas Use welding grade shielding gas; change to different gas Dirty welding wire Use clean, dry welding wire Eliminate pick up of oil or lubricant on welding wire...

Ngày tải lên: 27/06/2014, 17:20

Tài liệu Welders Handbook For Gas Shielded Arc Welding, Oxy Fuel Cutting & Plasma Cutting pptx

... CONTENTS Introduction Fusion welding Why use welding? Arc welding processes Welding terms MIG/MAG welding TIG welding 10 Plasma welding 17 Welding sheet 18 Welding plate 20 Welding pipes 22 Defects ... recommended gas for TIG welding aluminium and copper) See pages 2628 for choosing the right gas Tungsten inert gas welding Principles Tungsten inert gas shielded welding is usually called TIG welding ... from the arc melts the metal and the gas jet removes the molten metal from the cut ceramic shroud tungsten electrode plasma gas shielding gas plasma (arc) stream 44 WwW.oto-hui.com PLASMA ARC CUTTING...

Ngày tải lên: 25/02/2014, 10:20

Guidelines To Gas Tungsten Arc Welding (GTAW)_2 docx

... Merge and − GUIDELINES FOR GTAW WELDING (TIG) 6-1 Lift -Arc And HF TIG Start Procedures Lift -Arc Start When Lift-Arct button light is On, start arc as follows: Lift -Arc Start Method “Touch” 1−2 Seconds ... Simpo PDF MergeSECTION − TIG SHIELDING GASES and Split Unregistered Version - http://www.simpopdf.com 5-1 TIG Shielding Gases See page 38 in Gas Tungsten Welding book, available through MILLER ... from being transferred across the arc S For welding thin metals, use a 3/32 in diameter tungsten Compared to a balled tungsten, a pointed electrode provides greater arc control and lets you direct...

Ngày tải lên: 20/06/2014, 17:20

Guidelines For Shielded Metal Arc Welding (SMAW)_3 pptx

... SECTION − WELDING TROUBLESHOOTING 4-1 Porosity Porosity − small cavities or holes resulting from gas pockets in weld metal Possible Causes Corrective Actions Arc length too long Reduce arc length ... amperage Improper welding technique Place stringer bead in proper location(s) at joint during welding Adjust work angle or widen groove to access bottom during welding Momentarily hold arc on groove ... Practice technique 4-8 Distortion Distortion − contraction of weld metal during welding that forces base metal to move Base metal moves in the direction of the weld bead Possible Causes Excessive...

Ngày tải lên: 20/06/2014, 17:20

Guidelines To Gas Tungsten Arc Welding (GTAW) pot

... doctor before going near arc welding, gouging, or spot welding operations FLYING METAL can injure eyes • • Welding, chipping, wire brushing, and grinding cause sparks and flying metal As welds cool, ... SECTION − GUIDELINES FOR GTAW WELDING (TIG) 6-1 Lift -Arc And HF TIG Start Procedures Lift -Arc Start When Lift-Arct button light is On, start arc as follows: Lift -Arc Start Method “Touch” 1−2 Seconds ... SECTION − TIG SHIELDING GASES 5-1 TIG Shielding Gases See page 38 in Gas Tungsten Welding book, available through MILLER Electric, for more information about shielding gases 5-2 Argon vs Helium...

Ngày tải lên: 27/06/2014, 05:20

SMAW (Pro Series): Welding Guidelines For Shielded Metal Arc Welding pot

... PRINCIPLES OF SHIELDED METAL ARC WELDING (SMAW) SECTION − SHIELDED METAL ARC WELDING (SMAW) PROCEDURE 3-1 Typical Stick Welding Set-Up ... before welding or going near welding operations If cleared by your doctor, then following the above procedures is recommended SECTION − PRINCIPLES OF SHIELDED METAL ARC WELDING (SMAW) Shielded Metal ... ARC WELDING (SMAW) Shielded Metal Arc Welding (SMAW) or Stick welding is a process which melts and joins metals by heating them with an arc between a coated metal electrode and the workpiece...

Ngày tải lên: 27/06/2014, 05:20

ProcessesStick (SMAW) WeldingGuidelines For Shielded Metal Arc Welding potx

... PRINCIPLES OF SHIELDED METAL ARC WELDING (SMAW) SECTION − SHIELDED METAL ARC WELDING (SMAW) PROCEDURE 3-1 Typical Stick Welding Set-Up ... before welding or going near welding operations If cleared by your doctor, then following the above procedures is recommended SECTION − PRINCIPLES OF SHIELDED METAL ARC WELDING (SMAW) Shielded Metal ... ARC WELDING (SMAW) Shielded Metal Arc Welding (SMAW) or Stick welding is a process which melts and joins metals by heating them with an arc between a coated metal electrode and the workpiece...

Ngày tải lên: 27/06/2014, 08:20

Guidelines To Gas Tungsten Arc Welding (GTAW) WARNINGARC WELDING ppt

... doctor before going near arc welding, gouging, or spot welding operations FLYING METAL can injure eyes • • Welding, chipping, wire brushing, and grinding cause sparks and flying metal As welds cool, ... SECTION − GUIDELINES FOR GTAW WELDING (TIG) 6-1 Lift -Arc And HF TIG Start Procedures Lift -Arc Start When Lift-Arct button light is On, start arc as follows: Lift -Arc Start Method “Touch” 1−2 Seconds ... SECTION − TIG SHIELDING GASES 5-1 TIG Shielding Gases See page 38 in Gas Tungsten Welding book, available through MILLER Electric, for more information about shielding gases 5-2 Argon vs Helium...

Ngày tải lên: 27/06/2014, 17:20

ARC WELDING ELECTRODE

... ELECTRODES TESTING OF ELECTRODES 03/12/14 ARC WELDING ELECTR HISTORY OF ARC WELDING COATED ELECTRODE During first stage of work with metal arc welding a bare electrode was in use which was ... electrodes will not be uniform 03/12/14 ARC WELDING ELECTR 29 TEMPERATURE REGULATOR BAKING OVEN 03/12/14 ARC WELDING ELECTR 30 POTABLE OVEN 03/12/14 ARC WELDING ELECTR 31 When the electrodes are ... GRIPPING D = COVERING DIA , d= CORE DIA 03/12/14 ARC WELDING ELECTR TYPES OF ELECTRODE Arc welding electrodes are classified in groups by American Welding Society (AWS a5.1-91) based upon their...

Ngày tải lên: 12/03/2014, 16:49

ARC WELDING pdf

... material Stellite in the form of steel (BT-906T) 10 Arc Welding PTA Process Welding current Welding speed Plasma gas flow rate Shield gas Carrier gas Feed rate Constrictor nozzle diameter/ convergence ... weldment 31 Fusion Welding with Indirect Electric Arc 0.88 0.86 0.84 Submerged Arc Welding 0.82 0.80 Iscc 0.78 Metal Inert Gas 0.76 0.74 0.72 0.70 0.68 Indirect Electric Arc 0.66 0.64 0.62 25 ... of Aluminium 5083-H111 Welded Using Gas Metal Arc Welding Method 177 Kalenda Mutombo and Madeleine du Toit Part Mechanisms, Models, and Measurements of Arc Welding 219 Chapter 10 The Mechanism...

Ngày tải lên: 26/06/2014, 23:21

Arc Welding 2011 Part 2 potx

... is based on using the gas metal arc welding process (GMAW) In this instance, however, fusion of the base metal is not realized by the direct contact between the electric arc and the work pieces ... inert gas (MIG) process in which fusion of the base metal is not caused by direct contact with the electric arc Instead, the electric arc is established between the filler metal and feed metal, ... electric arc welding processes, the electric arc is established between the electrode and the base metal The high energy developed by the electric arc is in direct contact with base metal and...

Ngày tải lên: 12/08/2014, 05:20

Arc Welding 2011 Part 4 pptx

... robot As commented before, the arc spot welding was originally made manually using SMAW With the robot, the arc spot welding would be made with GMAW (Gas Metal Arc Welding) , being, therefore, unnecessary ... manually carried through with the GTAW process (Gas Tungsten Arc Welding) and coated electrode - SMAW (Shielded Metal Arc Welding) The manual welding is not just ergonomically improper to the ... reference and the actual arc length measured from the electric arc One solution for the problem of measuring the arc length would be to measure the voltage in electric arc (Varc), since they are...

Ngày tải lên: 12/08/2014, 05:20

Arc Welding 2011 Part 5 pot

... automatic welding process MIG/MAG ( "Metal Inert Gas/ Metal Active Gas" ) or the direct observation of the welding pool related to the control of current, voltage, wire speed and torch welding speed ... (deg) (deg) Wa α δ Arc voltage Welding current Arc radiation lost coefficient Wire feed rate Travel speed Wire radius Wall cross length with molten metal and arc (front view) Arc length Seam floor ... costs Fig Gas flow variation – CUSUM LS Filter Fig Gas flow variation – proposed algorithm 88 Arc Welding Fig Gas flow variation – Brandt algorithm 2.2 Infrared monitoring During the welding process,...

Ngày tải lên: 12/08/2014, 05:20

Arc Welding 2011 Part 9 potx

... about the shielding gas used for welding austenitic stainless steels Tusek & Suban (2000), for instance, studied the effect of hydrogen in argon as the shielding gas for arc welding of this stainless ... welded structures (optimized filler metal and gas selection) 154 Arc Welding Materials and experimental procedure In this study two different types of wires for GMA welding, namely ER430Ti and ER430LNb ... that the welding of ferritic stainless steels with filler metals also made of ferritic stainless steels minimizes the metallurgical discontinuity around the weld bead and promotes better metallurgical...

Ngày tải lên: 12/08/2014, 05:20