Integration of high k oxides with wide band gap semiconductors

Integration of high k oxides with wide band gap semiconductors

... integration of high- k dielectric with wide band- gap semiconductors 11 1.4 Research approaches 14 1.4.1 Nitridation treatment 14 1.4.2 Band offsets at high- k/ wide band- gap semiconductor ... offset and valence band offset between high- k dielectrics and wide band- gap semiconductors, respectively Band offsets above eV is one of the key criteria in t...

Ngày tải lên: 10/09/2015, 15:52

Báo cáo "The role of color luminescence centers Mn, Cu, Co in the semicondutors with wide band gap ZnS, ZnO and their applications " pptx

... by Cu2+, Mn2+, Co2 + ions [7-11] In this paper, we study the role of color luminescence centers Cu, Mn, Co in the semiconductors with wide band gap of ZnS, ZnO and test application of ZnS:Cu material ... band is greater than that of the blue band As increasing the concentration of Cu, the intensity of the blue band decreases whi...

Ngày tải lên: 22/03/2014, 11:20

Báo cáo khoa học: Nigrocin-2 peptides from Chinese Odorrana frogs – integration of UPLC/MS/MS with molecular cloning in amphibian skin peptidome analysis pot

... Alignment of amino acid residues in (A) nigrocin-2- related peptides from O schmackeri skin, (B) nigrocin-2- related peptides from O grahami skin, and (C,D) identical nigrocin-2- related peptides from ... feature of nigrocin-2 peptides is reminiscent of the glycine ⁄ leucine-rich dermaseptin orthologues from the skins of neotropical phyllomedusine leaf frogs,...

Ngày tải lên: 15/03/2014, 10:20

Báo cáo hóa học: " Polycrystallization effects on the nanoscale electrical properties of high-k dielectrics" doc

... (EOT) [17] The impact of the polycrystallization of the Al O layer on the electrical conduction of the gate stack has been analyzed at the nanoscale from current and CPD images obtained on fresh ... strength of the grain boundaries Finally, the influence of the environment conditions on the study of polycrystalline high-k dielectrics was also anal...

Ngày tải lên: 21/06/2014, 06:20

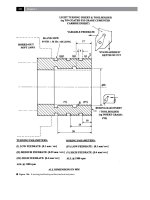

Machining of High Strength Steels With Emphasis on Surface Integrity by air force machinability data center_1 pot

... are the turned, bored and milled dimensions Machinability and Surface Integrity ‘full’ production operational machining, meaning that with some degree of confidence, manufacturing dictates and ... in these doubtful situations, rather than ‘working blindly’ – with no relevant cutting data, to base the applied cutting conditions upon Several of these ‘ranking’ non -machining te...

Ngày tải lên: 21/06/2014, 22:20

Machining of High Strength Steels With Emphasis on Surface Integrity by air force machinability data center_2 docx

... present in a data set into ‘components’ Each ‘component’ is attributed to an identifiable cause, or source of variation; in addition, one ‘component’ represents the variation due to uncontrolled ... meaningful machinability assessment 7.2 Machined Roundness Roundness is a condition of a surface of revolution’ , which can take the form of a: cylinder, cone, or sphere, where all th...

Ngày tải lên: 21/06/2014, 22:20

Machining of High Strength Steels With Emphasis on Surface Integrity by air force machinability data center_4 pot

... magnitude of the output of a system with respect to that of the input – the conditions of operation and measurements must be specified’ (Smith, 1993, et al.) of increasing the frictional contact ... tooling with the greatest possible diameter with the minimum of tool overhang By way of a caution concerning chatter frequency, this normally occurs near the most flexible vi...

Ngày tải lên: 21/06/2014, 22:20

Machining of High Strength Steels With Emphasis on Surface Integrity by air force machinability data center_5 pdf

... 160. Surface texture comprises of: ‘long-’, ‘medium-’ and ‘short-components’, together with the ‘direction of the dominant pattern’ – superimposed upon each other [Courtesy of Taylor Hobson] Machinability ... rotational speed (Vr) oscillation speed (Vo), the length and position of the honing stroke, the honing stick pressure (Vc) The inclination angle of the cross-honing actio...

Ngày tải lên: 21/06/2014, 22:20

Machining of High Strength Steels With Emphasis on Surface Integrity by air force machinability data center_7 ppt

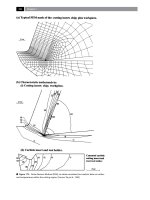

... NB This rate of heat generation only exists within the primary and secondary deformation zones By way of example of how the temperature generation/distribution occurs in orthogonal cutting, ... ‘regression line’ being the equivalent of the ‘least squares line’ , allows data on each axes to be compared – with some degree of confidence.(Wild, et al.,1995) Machinability and...

Ngày tải lên: 21/06/2014, 22:20

Machining of High Strength Steels With Emphasis on Surface Integrity by air force machinability data center_8 doc

... deformation – occurs when high pressures (i.e compression) are exerted on the cutting edge in combination with elevated temperatures Conditions likely to create plastic deformation on the cutting ... only the surface is ‘skimmed’ by a longitudinal turning operation • Notch wear on insert’s trailing edge – occurs by in the main, by adhesion wear, but to a lesser extent, may b...

Ngày tải lên: 21/06/2014, 22:20

Machining of High Strength Steels With Emphasis on Surface Integrity by air force machinability data center_9 docx

... in conjunction with the application of efficient cutting conditions The following simple formula can be utilised to calculate the ROI for a particular: production operation; machine tool; machining ... and Surface Integrity as a result, offer extremely fast process response, in comparison to those of the of the ‘non-rigid type’ – having long measurement paths (i.e found in conve...

Ngày tải lên: 21/06/2014, 22:20

Machining of High Strength Steels With Emphasis on Surface Integrity by air force machinability data center_10 ppt

... component, FC = cutting force component, FN = normal force component on the shear plane, FS = shear force component on shear plane, R = resultant tool force component, N = normal force component ... ‘frictional laws’ with the observation that: ‘The coefficient of friction* is substantially independent of the speed of sliding.’ *Coefficient of friction (µ) = F/N Thus, t...

Ngày tải lên: 21/06/2014, 22:20

Machining of High Strength Steels With Emphasis on Surface Integrity by air force machinability data center_11 pot

... taper-section overcomes the limitation of perpendicular sectioning By taking an Machinability and Surface Integrity 363 Figure 186. The effects of residual stress and deformations of a workpiece by machining ... component The concept of the overall functional performance of a surface and its accompanying sub -surface condition was recognised by Field and Kahles (19...

Ngày tải lên: 21/06/2014, 22:20

Machining of High Strength Steels With Emphasis on Surface Integrity by air force machinability data center_12 pptx

... ‘white-layer’ region extends to quite a small depth beneath the surface, in the region of 10 to 100 µm, depending upon the severity of the ‘abusive regime’ of surface generation Considering Fig 191 once again, ... of tensile residual stress was apparent in the immediate surface region Here, directly under this tensile stress zone, the stress concentration changed to one of comp...

Ngày tải lên: 21/06/2014, 22:20

Machining of High Strength Steels With Emphasis on Surface Integrity by air force machinability data center_13 doc

... Soc of Metals (Ohio), 1975 Preliminary Study of Variations in Machinability of Carbon Steel PERA Pub No 179, April 1968 Kaczmarek, J Principles of Machining by Cutting, Abrasion and Erosion Peter ... Properties of Engineering Materials Hodder and Stoughton Educ., 1979 Influence of Metallurgy on Hole Making Operations American Soc of Metals (Ohio), 1978 Influence of Met...

Ngày tải lên: 21/06/2014, 22:20