Machinery Components Maintenance And Repair Episode 2 Part 12 ppsx

Machinery Components Maintenance And Repair Episode 1 Part 3 ppsx

... flat- ness and fit of the surfaces with lead wire or Plasti-Gage đ , or simply better 54 Machinery Component Maintenance and Repair Figure 2 - 13 . Rotor history chart. Chapter 3 Machinery Foundations and Grouting* What’s ... associated with the machinery train should also be checked and calibrated. Again, a list and adequate record keeping prac- 50 Machinery Component...

Ngày tải lên: 05/08/2014, 12:20

Machinery Components Maintenance And Repair Episode 1 Part 12 docx

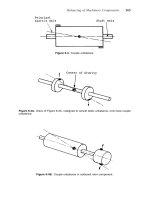

... inozin=◊ ◊ =◊600 16 0 0005 4 8 Ulbozlbinozin=◊◊ = 1 400 16 0 0005 11 2, e oz in oz in= ◊ ◊ = 10 2 000 0 4 0 012 5 . ,. 274 Machinery Component Maintenance and Repair Figure 6 -13 . Unbalance resulting ... . ein Uozin Woz . . () = ◊ () () e oz in oz in= ◊ = 10 1 000 0 01 . , 10 1 000oz in oz e◊= ◊., Balancing of Machinery Components 2 71 Figure 6 -10 . Disc-shap...

Ngày tải lên: 05/08/2014, 12:20

Machinery Components Maintenance And Repair Episode 2 Part 1 pps

... have the 318 Machinery Component Maintenance and Repair 322 Machinery Component Maintenance and Repair Figure 6-34. Balance tolerance nomogram for G -2. 5 and G-6.3, small rotors. 328 Machinery ... Inspection G4000-G40 -10 percent +10 percent G16-G2.5 -15 percent +15 percent G1 -20 percent +20 percent G0.4 -30 percent +30 percent 7. Plot the logged results as shown in F...

Ngày tải lên: 05/08/2014, 12:20

Machinery Components Maintenance And Repair Episode 2 Part 2 pdf

... balancing. 3 62 Machinery Component Maintenance and Repair 6-B-4 Balancing of Machinery Components 361 6-B-3 Appendix 6-C Balancing and Vibration Standards Balancing Standards ISO 1 925 Balancing ... Broadway New York, NY 10018 364 Machinery Component Maintenance and Repair * 1 ISO = International Standard Organization, Geneva, Switzerland. * 2 Draft International...

Ngày tải lên: 05/08/2014, 12:20

Machinery Components Maintenance And Repair Episode 2 Part 3 ppt

... its 38 4 Machinery Component Maintenance and Repair Figure 7-11. Pressure may be applied in either direction with shoulders of equal height. Ball Bearing Maintenance and Replacement 37 3 Table 7 -3 Ball ... Bearing Maintenance and Replacement 38 1 Figure 7-5. Bearing puller with two claws. Figure 7-6. Using arbor press and split ring to remove bearing from shaft. Part...

Ngày tải lên: 05/08/2014, 12:20

Machinery Components Maintenance And Repair Episode 2 Part 4 ppt

... shaft. 4. If mounted DF with the outer rings floating instead of DB, the bearing may be loose and have no preload. In addition, the balls 4 12 Machinery Component Maintenance and Repair Figure 7- 42 . ... located. Using a dial type indicator, find the point and mark it with a crayon so 4 02 Machinery Component Maintenance and Repair Figure 7 -28 . A hand gauge may be...

Ngày tải lên: 05/08/2014, 12:20

Machinery Components Maintenance And Repair Episode 2 Part 5 ppt

... characteristics 424 Machinery Component Maintenance and Repair Figure 7 -53 . Check internal contact surfaces by turning outer ring slowly while holding inner ring. 430 Machinery Component Maintenance and Repair Figure ... the etched “V” point- ing in the direction of predominant thrust. 422 Machinery Component Maintenance and Repair Figure 7- 52 . Preloaded thrust...

Ngày tải lên: 05/08/2014, 12:20

Machinery Components Maintenance And Repair Episode 2 Part 6 pot

... 14.0 MONEL* 0. 12 2.0 2. 5 — 63 .0– — bal. 400 70.0 MONEL* 0.13 1.5 2. 0 — 63 .0– — bal. Al 2. 8 K-500 70.0 Ti 0 .6 NITRONIC* 0. 06 4.0– bal. 20 .5– 11.5– 1.5–3.0 — Cb 0.1–0.3 50 (XM-19) 6. 0 23 .5 13.5 V ... 0.1–0.3 N 0 .2 0.4 FERRALIUM* 0.04 0.8 bal. 25 .5 5 .2 3.5 1.7 N 0.17 A 63 8 Gr 66 0 .08 2. 0 bal. 13.5– 24 .0– 1.0–1.5 — Al .35 16. 0 27 .0 B .001– .01 Ti 1.9 2. 35 V...

Ngày tải lên: 05/08/2014, 12:20

Machinery Components Maintenance And Repair Episode 2 Part 7 pdf

... 484 Machinery Component Maintenance and Repair Table 8-4—cont’d Typical Field and Shop Repair Services Offered by Process Machinery Repair Shops 6 ,7 Repair Operations Machinery Repairs— Field ... 1 / 4 inch Repair and Maintenance of Rotating Equipment Components 483 Table 8-4 Typical Field and Shop Repair Services Offered by Process Machinery Repair Sho...

Ngày tải lên: 05/08/2014, 12:20

Machinery Components Maintenance And Repair Episode 2 Part 8 pot

... specifications are used in the selection and Repair and Maintenance of Rotating Equipment Components 493 Figure 8- 30. The impeller shown in Figure 8 -29 after weld repair and final machining. The impeller ... between components (i.e., impellers, spacer sleeves, etc.) is provided. 5 12 Machinery Component Maintenance and Repair Chapter 9 Centrifugal Compressor Rotor...

Ngày tải lên: 05/08/2014, 12:20

Machinery Components Maintenance And Repair Episode 2 Part 9 pps

... fatigue of this nature occurs 538 Machinery Component Maintenance and Repair Protecting Machinery Parts Against Loss of Surface 5 39 in rolling-element bearings, rails, and other surfaces subjected ... through the compressor, and internal 522 Machinery Component Maintenance and Repair installing. After they are installed, look again! The O-rings must be between the bac...

Ngày tải lên: 05/08/2014, 12:20

Machinery Components Maintenance And Repair Episode 2 Part 10 ppt

... 6.00 1.00 13.00 2. 70 BAL 5 .2 Ti 62 FeMn-1 D 0.44 0. 52 14 .10 16.60 BAL 20 FeMn -2 D 0.64 0 .26 0.47 13.60 BAL 20 Co-1 + 1 .20 2. 06 30.00 4.50 BAL 2. 00 3.00 3.00 1.5 Mo 40 Co -2 + 1.80 29 .0 9.00 BAL 50 Co-3 ... D 0.18 0.30 2. 90 1. 02 BAL 35 Fe -2 D 0.68 0.47 6.80 1.48 BAL 20 FeCr-1 D 2. 20 0.90 30.00 1.30 BAL 3.8 Mo 1.50 Ti 50 FeCr -2 D 0.44 1 .20 29 .60 1.70...

Ngày tải lên: 05/08/2014, 12:20

Machinery Components Maintenance And Repair Episode 2 Part 11 doc

... 3, 325 + Cast iron 6.6 0. 12 2,500 Steels 6 .2 6.6 0 .11 2, 700 2, 800 Aluminum 12 13 0. 52 1 ,21 6 Copper 9.1 0. 92 1,981 Deterioration in Storage. Some synthetic rubbers such as neoprene and Buna N are sensitive ... weight 2. 506 56.0 0.849 18.9 3.0 : 1 Second ring loss in weight 2. 586 57.8 0.9 72 21.8 2. 6 : 1 Oil ring loss in weight 1 .26 0 46.5 0.865 31.9 1.5 : 1 566 Machi...

Ngày tải lên: 05/08/2014, 12:20

Machinery Components Maintenance And Repair Episode 2 Part 12 ppsx

... .070 .103 .139 .21 0 .27 5 1.78 2. 62 3.53 5.33 6.99 Diameter STATIC SEALING A Gland Depth .048 .077 .109 .168 .22 2 1 .22 1.96 2. 77 4 .27 5.64 .054 .083 .115 .176 .23 2 1.37 2. 11 2. 92 4.47 5.89 B Groove ... .088 . 120 .184 .23 4 1.40 2. 24 3.05 4.67 5.94 .057 .090 . 124 .188 .24 0 1.45 2. 29 3.15 4.76 6.10 B Groove Width .090 .140 .180 .28 0 .370 2. 29 3.56 4.57 7.11 9.40 .100...

Ngày tải lên: 05/08/2014, 12:20

Machinery Components Maintenance And Repair Episode 2 Part 13 pptx

... 21 2 21 3, 21 3f, 25 3, 25 4f OPTALIGN system, for use in, 21 2 21 3, 21 3f reverse-indicator method of, 20 5, 20 8 21 0, 20 9f, 22 8, 22 9f, 23 0f, 23 1f reverse-indicator with clamp-on jigs method of, 20 5, 20 7f reverse-indicator ... causing, 26 0 phase angle of, 28 0, 28 3 quasi-static condition of, 26 6, 26 6f, 26 7f resonance in, 26 8 26 9 static or force, 26 2 26...

Ngày tải lên: 05/08/2014, 12:20

- machinery component maintenance and repair

- machinery component maintenance and repair download

- machinery component maintenance and repair free download

- machinery component maintenance and repair pdf

- maintenance and repair of machinery components

- prime minister and i episode 2 eng

- prime minister and i episode 2 eng sub gooddrama

- routine maintenance and repair