shielded metal arc cutting

Guidelines For Shielded Metal Arc Welding (SMAW)_3 pptx

... − small cavities or holes resulting from gas pockets in weld metal Possible Causes Corrective Actions Arc length too long Reduce arc length Workpiece dirty Remove all grease, oil, moisture, rust, ... length too long or voltage Reduce arc length or voltage too high 4-3 Incomplete Fusion Incomplete Fusion − failure of weld metal to fuse completely with base metal or a preceeding weld bead Possible ... technique Adjust travel speed 4-6 Burn-Through Burn-Through − weld metal melting completely through base metal resulting in holes where no metal remains Possible Causes Excessive heat input Corrective...

Ngày tải lên: 20/06/2014, 17:20

SMAW (Pro Series): Welding Guidelines For Shielded Metal Arc Welding pot

... PRINCIPLES OF SHIELDED METAL ARC WELDING (SMAW) Shielded Metal Arc Welding (SMAW) or Stick welding is a process which melts and joins metals by heating them with an arc between a coated metal electrode ... SECTION − PRINCIPLES OF SHIELDED METAL ARC WELDING (SMAW) SECTION − SHIELDED METAL ARC WELDING (SMAW) PROCEDURE ... Electrode Holder Position Arc Length Arc length is the distance from the electrode to the workpiece A short arc with correct amperage will give a sharp, crackling sound Correct arc length is related...

Ngày tải lên: 27/06/2014, 05:20

ProcessesStick (SMAW) WeldingGuidelines For Shielded Metal Arc Welding potx

... PRINCIPLES OF SHIELDED METAL ARC WELDING (SMAW) Shielded Metal Arc Welding (SMAW) or Stick welding is a process which melts and joins metals by heating them with an arc between a coated metal electrode ... SECTION − PRINCIPLES OF SHIELDED METAL ARC WELDING (SMAW) SECTION − SHIELDED METAL ARC WELDING (SMAW) PROCEDURE ... Electrode Holder Position Arc Length Arc length is the distance from the electrode to the workpiece A short arc with correct amperage will give a sharp, crackling sound Correct arc length is related...

Ngày tải lên: 27/06/2014, 08:20

Guidelines For Gas Metal Arc Welding (GMAW)_1 doc

... GAS METAL - http://www.simpopdf.com Simpo PDF Merge and Split Unregistered Version ARC WELDING (GMAW) Gas Metal Arc Welding (GMAW) is a welding process which joins metals by heating the metals ... metals to their melting point with an electric arc The arc is between a continuous, consumable electrode wire and the metal being welded The arc is shielded from contaminants in the atmosphere ... cable with good metal- to -metal contact to workpiece or worktable as near the weld as practical Insulate work clamp when not connected to workpiece to prevent contact with any metal object Do...

Ngày tải lên: 20/06/2014, 17:20

SMAW (Pro Series): Welding Guidelines For Shielded Metal ppt

... SECTION − GAS METAL ARC WELDING (GMAW) Gas Metal Arc Welding (GMAW) is a welding process which joins metals by heating the metals to their melting point with an electric arc The arc is between ... spray arc transfer S Welding is limited to flat positions and horizontally fillet welds S Welding is limited to metal 1/8 inch (3 mm)or thicker Ref 804 879-A 3-3 Spray Arc Transfer 1 Spray Arc ... Transfer 1 Spray Arc Transfer Spray arc transfer “sprays” a stream of tiny molten droplets across the arc, from the electrode wire to the base metal Spray arc transfer uses relatively high voltage,...

Ngày tải lên: 27/06/2014, 05:20

Processes MIG (GMAW) WeldingGuidelines For Gas Metal Arc Welding pot

... SECTION − GAS METAL ARC WELDING (GMAW) Gas Metal Arc Welding (GMAW) is a welding process which joins metals by heating the metals to their melting point with an electric arc The arc is between ... spray arc transfer S Welding is limited to flat positions and horizontally fillet welds S Welding is limited to metal 1/8 inch (3 mm)or thicker Ref 804 879-A 3-3 Spray Arc Transfer 1 Spray Arc ... Transfer 1 Spray Arc Transfer Spray arc transfer “sprays” a stream of tiny molten droplets across the arc, from the electrode wire to the base metal Spray arc transfer uses relatively high voltage,...

Ngày tải lên: 27/06/2014, 17:20

Perform routine manual metal arc welding (MMAW)

... reduction in the arc s penetration 70-80º 5.12A Perform routine MMAW Fundamentals of MMAW Arc length, ie: the distance from the tip of the electrode to the work piece The correct arc length is dependent ... pool This can cause slag inclusion and a reduction in the arc s penetration Element 5.12A.4 Perform routine welding using Manual Metal Arc Welding In this element you will be required to achieve ... weld - 30º 5.12A Perform routine MMAW Weld terminology – fillet welds Parent metal Leg length Reinforcement Weld metal Toe Fusion zone Penetration Heat effected zone 5.12A Perform routine MMAW...

Ngày tải lên: 16/02/2017, 21:10

Weld using gas metal arc welding process (GMAW)

... gas metal arc welding shielding gas identifying the modes of metal transfer in gas metal arc welding consumables comparison between GMAW and MMAW spot welding 5.17A Weld using gas metal arc ... using gas metal arc welding process (GMAW) Fillet weld terms Parent Metal Leg Length Reinforcement Weld Metal Toe Fusion Zone Penetration Heat Effected Zone 5.17A Weld using gas metal arc welding ... process (GMAW) The gas metal arc welding process An electric arc is formed between a wire and the workplace Once arc established the wire is fed from a wire spool into the arc to form a weld...

Ngày tải lên: 16/02/2017, 21:20

Tài liệu Welders Handbook For Gas Shielded Arc Welding, Oxy Fuel Cutting & Plasma Cutting pptx

... parent metal melt run Melting the parent metal by passing a TIG arc along the surface Filler metal is not used bead A single run of weld metal deposited onto the surface of the parent metal nozzle ... the arc melts the metal and the gas jet removes the molten metal from the cut ceramic shroud tungsten electrode plasma gas shielding gas plasma (arc) stream 44 WwW.oto-hui.com PLASMA ARC CUTTING ... by constricting an arc between a tungsten electrode and the component Plasma arc cutting is characterised by fast cutting speeds and is mainly used in mechanised systems The cutting is accompanied...

Ngày tải lên: 25/02/2014, 10:20

Welding Automation Submerged Arc, TIG, MIG/MAG COMPLETE SOLUTIONS IN WELDING AND CUTTING FROM ESAB doc

... challenges of the metal fabrication industry Quality Welds- Every Time ESAB offers the widest range of filler metals in the world Our goal is to provide the most productive filler metal for your ... required) Guide wheel, fillet Magnetic guide rail, 3m Carbon arc gouging Rebuilding kit carbon arc gouging VEC-motor, 312:1 to be used for carbon arc gouging 12 0334 291 889 0153 872 880 0416 492 880 ... standard Welding Automation The 21st Century has brought many new challenges to the metal fabrication industry Metal fabricators must meet the demand for increased quality while providing their...

Ngày tải lên: 25/03/2014, 07:20

Manufacturing metal cutting

... 15 BASIC CUTTING TOOLS 4.1 CUTTING SPEEDS, FEEDS, TOOLS AND TIMES • Cutting is a balance between a number of factors, - cutting slowly will add costly time to manufacturing operations - cutting ... correct? a) the cutting pressure drops as cutting velocity increases b) power required drops as metal temperature and cutting velocity increase c) we can use the quantity of metal removed by ... might we be cutting? What roles rake and relief angles play in cutting tools? ans the rake angle will change the basic cutting parameters A positive rake (sharp tool) will give lower cutting forces,...

Ngày tải lên: 08/04/2014, 11:18

Reduce Vibration in Metal Cutting 2011 Part 1 docx

... vibrations in your metal cutting process For further information and assistance, please contact your local Sandvik Coromant representative Sandvik Coromant – How to reduce vibration in metal cutting Sandvik ... insert geometry Reduce the cutting speed Sandvik Coromant – How to reduce vibration in metal cutting Bad surface finish: Increase the coolant flow Choose an insert with a sharp cutting edge Check that ... choose a Silent Tool Sandvik Coromant – How to reduce vibration in metal cutting Select your tool system One application within metal cutting that is very sensitive to vibration is internal turning...

Ngày tải lên: 12/08/2014, 00:20

Reduce Vibration in Metal Cutting 2011 Part 2 pot

... steel boring bars - x D Silent Tools boring bars Rounded (ER treated) cutting edge Example: R166.0G-16MM01–150 Geometry F Sharp cutting edge Example: R166.0G-16MM01F150 Geometry C Chip breaking geometry...

Ngày tải lên: 12/08/2014, 00:20

Evaluation of metal‐ and PAH toxicity of thermo treated oil‐based drill cuttings by the use of DREAM sediment model

... of some heavy metals in sediment samples collected from the NCS 30 Average content of Heavy metal Heavy metal Heavy metal heavy metal in considered ... discharges of WBM cuttings -‐ The concentrations of oil, PAH and heavy metals in treated OBM cuttings are expected to be similar to those in WBM cuttings -‐ The ... copepods, uptake of metals from the dissolved phase and food ingestion can be equally important to metal accumulation Barite (and other heavy metals) also occurs naturally...

Ngày tải lên: 10/12/2016, 13:38

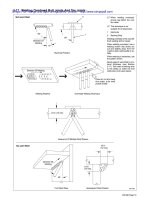

Hướng dẫn thiết kế chi tiết dạng tấm (Sheet metal)

... môi trờng Sheet Metal: Mở file mẫu Sheet Metal chọn mặt chi tiết file Part, sau chọn Application-> Sheet metal Hệ thống cho phép sử dụng công cụ Sheet Metal bổ sung tham số Sheet Metal tới file ... Sheet Metal Một chi tiết Sheet Metal có tham số mô tả chi tiết cách tạo Ví dụ Sheet Metal thờng có chiều dày mặt uốn cong thờng có bán kính Nút Sheet Metal Styles biểu tợng công cụ Sheet Metal ... đổi kiểu dạng Part Model mặc định thành Sheet Metal Kiểu Sheet Metal chi tiết chi tiết cho phép sử dụng công cụ Sheet Metal bổ sung tham số Sheet Metal Khi ta chuyển lại thành mô hình chi tiết...

Ngày tải lên: 27/08/2012, 13:54

The effects of clay a m e n d m e n t and composting on metal speciation in digested sludge liang qiao

... extracted metals seems to be related to the changes in metal speciation and will be discussed below Metal speciation To determine the effect of red mud on the speciation of metals in sludge, the metal ... of heavy metals Relationship of metal speciation and leachable metal Since a M MgC12 solution is a stronger extractant than a 0.01 M CaC12 solution for metals from cation sites, more metals can ... of metal speciation and plant available metal A comparison between the speciation of metals in the sludge compost and the metals extracted by DTPA is shown in Fig ! It can be seen that the Metal...

Ngày tải lên: 23/09/2012, 14:47

Heavy metal cation retention by unconventional sorbents (red muds and fly ashes)

... in heavy metal ions removal (Apak and Unseren, 1987) The aim of the present study is to develop costeffective unconventional sorbents, preferably metallurgical waste solids, for heavy metal removal ... needs to be shown so as to guarantee non-leachability of metals from the metal- loaded sorbents EXPEilIMENTAL Materials and methods All heavy metal solutions (divalent cations Of Pb, CA and Cu) were ... heavy metal hydroxide as the elution proceeds, and this layer may promote further binding of the metals enhancing sorption Generally very high limiting capacities have been achieved for metal...

Ngày tải lên: 23/09/2012, 14:47