introduction to root cause failure analysis

Bảo dưỡng công nghiệp 7 root cause failure analysis An essential element of Asset Integrity Management and Reliability Centered Maintenance Procedures

... sealing groove • The main cause of failure was overloading of the bearing Actions/recommendation: • Reanalysis by FEM and redesign Root Cause Failure Analysis Disclosed Failure of: O-RING • Four ... its ability to perform a design, manufacture, or required function operation that have led to a failure Failure Mode – The effect by which a failure is observed on the failed item Root Cause (RCA) ... underlying problem A Root Cause Analysis will disclose: Why the incident, failure or breakdown occurred How future failures can be eliminated by: – – – – – changes to procedures changes to operation...

Ngày tải lên: 15/10/2013, 15:06

ROOTCAUSE FAILURE ANALYSISI ROOT CAUSE FAILURE ANALYSIS PLANT ENGINEERING MAINTENANCE pot

... CONTENTS Part I1 Introduction to Root Cause Failure Analysis i Chapter Chapter Chapter Chapter Chapter Chapter Part I Introduction General Analysis Techniques Root Cause Failure Analysis Methodology ... ROOT CAUSE FAILURE ANALYSIS PLANT ENGINEERING MAINTENANCE SERIES Vibration Fundamentals R Keith Mobley Root Cause Failure Analysis R Keith Mobley Maintenance Fundamentals R Keith Mobley ROOT ... One, Introduction to Root Cause Failure Analysis, presents analysis techniques used to investigate and resolve reliability-related problems It provides the basic methodology for conducting a root...

Ngày tải lên: 14/03/2014, 18:20

![mobley rk root cause failure analysis [ heinmann 1999]](https://media.store123doc.com/images/document/14/ne/tk/medium_tkf1401863176.jpg)

mobley rk root cause failure analysis [ heinmann 1999]

... One, Introduction to Root Cause Failure Analysis, presents analysis techniques used to investigate and resolve reliability-related problems It provides the basic methodology for conducting a root ... CAUSE- AND-EFFECT ANALYSIS Cause- and-effect analysis is a graphical approach to failure analysis This also is referred to as fishbone analysis, a name derived from the fish-shaped pattern used to plot ... of potential causes to no more than two or three A method that can be used to evaluate potential factors that may have caused or contributed to the event is the cause- and-effect analysis Graphical...

Ngày tải lên: 04/06/2014, 13:26

ROOT CAUSE FAILURE ANALYSIS PLANT ENGINEERING MAINTENANCE II docx

... CONTENTS Part I1 Introduction to Root Cause Failure Analysis i Chapter Chapter Chapter Chapter Chapter Chapter Part I Introduction General Analysis Techniques Root Cause Failure Analysis Methodology ... ROOT CAUSE FAILURE ANALYSIS PLANT ENGINEERING MAINTENANCE SERIES Vibration Fundamentals R Keith Mobley Root Cause Failure Analysis R Keith Mobley Maintenance Fundamentals R Keith Mobley ROOT ... One, Introduction to Root Cause Failure Analysis, presents analysis techniques used to investigate and resolve reliability-related problems It provides the basic methodology for conducting a root...

Ngày tải lên: 27/06/2014, 17:20

ROOT CAUSE FAILURE ANALYSIS PLANT ENGINEERING MAINTENANCE SERIES Vibration Fundamentals R. Keith pot

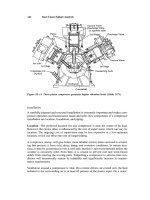

... Mobley Root Cause Failure Analysis R Keith Mobley Maintenance Fundamentals R Keith Mobley 20 | MOBLEY.FM Page iii Wednesday, March 3, 1999 2:29 PM ROOT CAUSE FAILURE ANALYSIS R Keith Mobley Boston ... TRENDING ANALYSIS 125 Chapter 15 FAILURE- MODE ANALYSIS 138 Chapter 16 SIGNATURE ANALYSIS 181 Chapter 17 ROOT- CAUSE ANALYSIS 189 Part III RESONANCE AND CRITICAL SPEED ANALYSIS ... its pistons from bottom-center to top-center and returns to bottom-center in each complete operation of the cylinder The mechanical forces generated by the reversal of direction at both top-center...

Ngày tải lên: 27/06/2014, 17:20

ROOT CAUSE FAILURE ANALYSIS PLANT ENGINEERING MAINTENANCE ppt

... CONTENTS Part I1 Introduction to Root Cause Failure Analysis i Chapter Chapter Chapter Chapter Chapter Chapter Part I Introduction General Analysis Techniques Root Cause Failure Analysis Methodology ... ROOT CAUSE FAILURE ANALYSIS PLANT ENGINEERING MAINTENANCE SERIES Vibration Fundamentals R Keith Mobley Root Cause Failure Analysis R Keith Mobley Maintenance Fundamentals R Keith Mobley ROOT ... One, Introduction to Root Cause Failure Analysis, presents analysis techniques used to investigate and resolve reliability-related problems It provides the basic methodology for conducting a root...

Ngày tải lên: 27/06/2014, 18:20

ROOT CAUSE FAILURE ANALYSIS.PLANT ENGINEERING MAINTENANCE SERIES Vibration Fundamentals pdf

... Mobley Root Cause Failure Analysis R Keith Mobley Maintenance Fundamentals R Keith Mobley 20 | MOBLEY.FM Page iii Wednesday, March 3, 1999 2:29 PM ROOT CAUSE FAILURE ANALYSIS R Keith Mobley Boston ... TRENDING ANALYSIS 125 Chapter 15 FAILURE- MODE ANALYSIS 138 Chapter 16 SIGNATURE ANALYSIS 181 Chapter 17 ROOT- CAUSE ANALYSIS 189 Part III RESONANCE AND CRITICAL SPEED ANALYSIS ... its pistons from bottom-center to top-center and returns to bottom-center in each complete operation of the cylinder The mechanical forces generated by the reversal of direction at both top-center...

Ngày tải lên: 27/06/2014, 18:20

Root Cause Failure Analysis Part 1 ppsx

... CONTENTS Part I1 Introduction to Root Cause Failure Analysis i Chapter Chapter Chapter Chapter Chapter Chapter Part I Introduction General Analysis Techniques Root Cause Failure Analysis Methodology ... ROOT CAUSE FAILURE ANALYSIS PLANT ENGINEERING MAINTENANCE SERIES Vibration Fundamentals R Keith Mobley Root Cause Failure Analysis R Keith Mobley Maintenance Fundamentals R Keith Mobley ROOT ... One, Introduction to Root Cause Failure Analysis, presents analysis techniques used to investigate and resolve reliability-related problems It provides the basic methodology for conducting a root...

Ngày tải lên: 11/08/2014, 21:23

Root Cause Failure Analysis Part 2 ppt

... of potential causes to no more than rwo or three A method that can be used to evaluate potential factors that may have caused or contributed to the event is the cause- and-effect analysis Graphical ... test series can be devel- 38 Root Cause Failure Analysis oped to confirm or eliminate the suspected cause of equipment failure As an example, hard-bluing can be used to verify the alignment and ... not available to the investigator Without this information, it is almost impossible to fully define the current or historical cost of a production system or area Root Cause Failure Analysis Methodology...

Ngày tải lên: 11/08/2014, 21:23

Root Cause Failure Analysis Part 3 pptx

... were taken to permit resumption of production 56 Root Cause Failure Analysis Causes and Long-Term Corrective Actions This section of the report should clearly describe the specific root cause( s) ... of highly hazardous chemicals into the workplace 68 Root Cause Failure Analysis To meet this requirement, a company must define an incident in terms specific to its facility This includes an ... by two variables: suction conditions and total system pressure or head requirements Total system pressure comprises 80 Root Cause Failure Analysis the total vertical lift or elevation change,...

Ngày tải lên: 11/08/2014, 21:23

Root Cause Failure Analysis Part 5 pdf

... divided into two major classifications: rotary and reciprocating 130 Root Cause Failure Analysis Rotary The rotary compressor is adaptable to direct drive by the use of induction motors or multicylinder ... is needed to dissipate the heat generated by the compression process If the unload frequency is too great, these compressors have a high probability of failure 136 Root Cause Failure Analysis ... by the work of compression plus friction caused by the action of the piston and piston rings on the cylinder wall and packing on 140 Root Cause Failure Analysis Figure 1&11 k a f spring configuration...

Ngày tải lên: 11/08/2014, 21:23

Root Cause Failure Analysis Part 6 pot

... by undercutting to prevent failure 166 Root Cause Failure Analysis Bearing-Support Shafts Many roll failures can be directly attributed to poor shaft design In these cases, the total span from ... not exceeded 158 Root Cause Failure Analysis This can be a real problem for baghouses that rely on automatic timers to control cleaning frequency The use of a timing function to control cleaning ... to augment the shaker-cleaning process 156 Root Cause Failure Analysis The gas entering the filter must be kept above its dewpoint to avoid water-vapor condensation on the bags, which will cause...

Ngày tải lên: 11/08/2014, 21:23

Root Cause Failure Analysis Part 7 potx

... and enters a correction factor to the inverter drive This factor compensates for the variation in speed, or slip, caused by load changes 194 196 Root Cause Failure Analysis Volts-per-hertz technology ... alternating-current motors in both high-torque and low-speed applications Alternating-current vector controls refer to the drive’s ability to control the vector sum of flux and torque in the controlled motor, ... efficient and extremely difficult to lubricate because of high tooth-contact pressures Further Figure Hypoid bevel gear (Neale 1993) 182 Root Cause Failure Analysis increasing the demands on...

Ngày tải lên: 11/08/2014, 21:23

Root Cause Failure Analysis Part 8 pot

... valve almost always will have a pointer indicator threaded onto the upper end of the stem to indicate the position of the gate 204 Root Cause Failure Analysis Figure 17-2 Non-rising-stem gate valve ... 218 Root Cause Failure Analysis Manual control devices (e.g., levers, cams, or palm buttons) can be used as the primary actuator on most fluid power control valves Normally, these actuators ... indicator set up as described previously, place the indicator stem well into the bore of the stuffing box, which should be concentric to the shaft axis to within a 0.005 in total indicator reading...

Ngày tải lên: 11/08/2014, 21:23

Root Cause Failure Analysis Part 9 pdf

... source of failure In most cases, valve failure is due to fatigue The only positive way to prevent or minimize 244 Root Cause Failure Analysis T b e 19-2 Common Failure Modes of Rohry-Type, Positive-DisplacementPumps ... required maintenance Symptoms The symptoms of failure due to variations in TSH include changes in motor speed and flow rate Motor Speed The brake horsepower of the motor that drives a pump is ... air or gas, and turbulent flow 239 240 Root Cause Failure Analysis Table 19-1 Common Failure Modes of Centrifugal Pumps THE CAUSES Bent Shaft Casing DktofW fmm Excessbe P i p Sbaln cavyatilm...

Ngày tải lên: 11/08/2014, 21:23

Root Cause Failure Analysis Part 10 pdf

... actuators are subject to actuator failure In many cases, these failures are the reason a valve fails to properly open, close, or seal Even w t manually controlled valves, the ih true root cause ... Pressure-volume-temperature RCFA Root cause failure analysis RCRA Resource Conservation and Recovery Act rpm Rotating speed rpm? Rotating speed, squared rpm3 Rotating speed, cubed 290 Root Cause Failure Analysis SARA ... to leakage, speed of operation, or complete valve failure Table 29-1 lists the more common causes of these failures Special attention should be given to the valve actuator when conducting a root...

Ngày tải lên: 11/08/2014, 21:23

Root Cause Failure Analysis Part 11 ppsx

... run -to- failure programs 300 Root Cause Failure Analysis primary event A direct, although possibly not obvious, contributor to the top event in a fault-tree analysis prime Add fluid to a pump to ... change, measured from centerline to centerline 298 Root Cause Failure Analysis longitudinal Pertaining to the lengthwise dimension lubricity The ability of a material to lubricate machine train A ... a fault-tree analysis; it can he either a broad, all-encompassing failure or a failure of a particular component torque A moment/force couple applied to a rotor such as a shaft to sustain acceleratiodload...

Ngày tải lên: 11/08/2014, 21:23

Root Cause Failure Analysis Episode 4 pot

... premature wear or failure Therefore, both suction and discharge piping must be adequately supported to prevent 88 Root Cause Failure Analysis strain In addition, flexible isolator connectors should ... Speed = Rotor Diameter x IC x Rotations per Minute (rpm) 102 Root Cause Failure Analysis Mechanical E@ciency True mechanical efficiency (ME) is equal to the total input power divided by the total ... operation Root Cause Failure Analysis 90 If a bypass loop is used, it must provide sufficient flow to assure reliable pump operation The bypass should provide sufficient volume to permit the pump to...

Ngày tải lên: 13/08/2014, 17:20

Tài liệu ME-430 INTRODUCTION TO COMPUTER AIDED DESIGNTORSIONAL ANALYSIS Using Pro/MECHANICA Pro/ENGINEER pptx

... Assign button, then Part - Pick the UJoint OK Click the Edit button Click on Failure Criterion tab U-Joint is made of steel, and steel is ductile The most suitable failure criteria is distortion ... the load as “TorsionLoad” Click the arrow button under the Surfaces Pick the top surface region previously created for applying the torsion load – see Figure below Click the arrow button under ... Click on button Change the type of Distribution to Total Load At Point Click on the arrow button under Distribution, and pick the datum point PNT0 Under Moment, enter 10000 in-lb torsion in the...

Ngày tải lên: 19/01/2014, 05:20

DESIGN OF MACHINERYAN INTRODUCTION TO THE SYNTHESIS AND ANALYSIS OF MECHANISMS AND MACHINES phần 2 potx

... moved slightly beyond the toggle position and against a fixed stop Any attempt to reverse the motion of the linkage then causes it merely to jam harder against the stop It must be manually pulled ... footnotet on p 81.) Figure 3-3b shows a torque T2 applied to link Even before any motion occurs, this causes a static, colinear force F34 to be applied by link to link at point D Its radial and tangential ... and perpendicular to link 4, respectively Ideally, we would like all of the force F 34 to go into producing output torque T on link However, only the tangential component creates torque on link...

Ngày tải lên: 08/08/2014, 12:23