Machining of High Strength Steels With Emphasis on Surface Integrity by air force machinability data center 9 docx

Machining of High Strength Steels With Emphasis on Surface Integrity by air force machinability data center_1 pot

... reservation, actual cutting data can be employed, which represents almost optimum machining conditions, leading the way to Table 9. A comparison of the machined component tes- tpiece accuracies by ... sucient precision to be of much practical use and by 199 9, Gorzkowski, et al., in their powder metallurgy paper concerning ‘secondary machining 1 , entitled: 1 ‘Secondar...

Ngày tải lên: 21/06/2014, 22:20

Machining of High Strength Steels With Emphasis on Surface Integrity by air force machinability data center_2 docx

... technique in conjunction with a strictly controlled and limited ma- chining strategy – based upon some form of ‘orthogo- nal array’ , in combination with the strength (i.e >5% ‘F-ratio’) of parameters ... situation is that surface texture continuously degen- erates, and it is only the burnishing (i.e.‘ironing’) of the surface that ‘masks’ the temporary improvement in mac...

Ngày tải lên: 21/06/2014, 22:20

Machining of High Strength Steels With Emphasis on Surface Integrity by air force machinability data center_4 pot

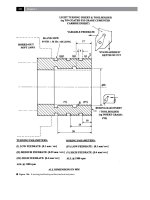

... following way: ‘e ratio of the magnitude of the output of a system with respect to that of the input – the conditions of operation and measure- ments must be specied’ (Smith, 199 3, et al.). • Cutting ... at high feedrates when high- speed machining. Machinability and Surface Integrity Figure 157. A chatter model, with potential chatter conditions and the appl...

Ngày tải lên: 21/06/2014, 22:20

Machining of High Strength Steels With Emphasis on Surface Integrity by air force machinability data center_5 pdf

... con- dition. Machinability and Surface Integrity Figure 163. Surface texture data- capture, with techniques for the derivation of the arithmetic roughness parameter: Ra. Machinability and Surface ... and position of the honing stroke, the hon- ing stick pressure (Vc). e inclination angle of the cross-hon- ing action, is a product of the up-/down-ward head motion (...

Ngày tải lên: 21/06/2014, 22:20

Machining of High Strength Steels With Emphasis on Surface Integrity by air force machinability data center_7 ppt

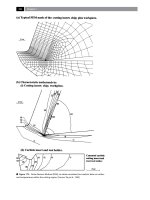

... ‘T’. NB is rate of heat generation only exists within the primary and secondary deformation zones. By way of example of how the temperature genera- tion/distribution occurs in orthogonal cutting, ... disappear and at the region of the tool (i.e. insert) only the conduction term remains. ∴ Rate of heat generation (˙q) = σ ˙ε Where: ‘σ’ was obtained from an emprical function o...

Ngày tải lên: 21/06/2014, 22:20

Machining of High Strength Steels With Emphasis on Surface Integrity by air force machinability data center_8 doc

... stages of dif- fusion are somewhat slow, due to the rate of diusion decreas- ing as the concentration gradient diminishes. (Higgins, 197 9) 65 ‘Atomic diusion process’ , there is strong evidence ... deformation – occurs when high pressures (i.e. compression) are exerted on the cutting edge in combination with elevated temperatures. Con- ditions likely to create plastic deformati...

Ngày tải lên: 21/06/2014, 22:20

Machining of High Strength Steels With Emphasis on Surface Integrity by air force machinability data center_9 docx

... application of the above equation for practical machining operations, due to the vast amount of machining data that is necessary to determine the parameters of this equation – producing considerable ... forming forces with very high- frequency acoustic emissions (AE). e application of AE in association with other Figure 177. The correlation of typical manufacturing c...

Ngày tải lên: 21/06/2014, 22:20

Machining of High Strength Steels With Emphasis on Surface Integrity by air force machinability data center_10 ppt

... thrust force component, • F C = cutting force component, • F N = normal force component on the shear plane, • F S = shear force component on shear plane, • R = resultant tool force component, • ... briey mentioned. Frictional Effects During Machining For simplicity’s sake, friction between dry sliding sur- faces will be concisely reviewed. In 1 699 Amontons ‘laws of fri...

Ngày tải lên: 21/06/2014, 22:20

Machining of High Strength Steels With Emphasis on Surface Integrity by air force machinability data center_11 pot

... 7.10 Surface Integrity of Machined Components – Introduction Previously in Section 7.5 concerning machined sur- face texture, the discussion was principally concerned with the resultant surface ... The eects of residual stress and deformations of a workpiece by machining. [After: Brinksmeier et al., 198 2] . Machinability and Surface Integrity Figure 185. The c...

Ngày tải lên: 21/06/2014, 22:20

Machining of High Strength Steels With Emphasis on Surface Integrity by air force machinability data center_12 pptx

... Cutting Forces in Machinability Evaluation. Proc. of FAIM 92 , CRC Press, Inc. (Florida), 93 7 94 6, 199 2. Ernst, H. and Merchant, M.E. Chip Formation, Friction and High Quality Machined Surfaces. ... Chapter Figure 1 89. The inuence of the cutting edge’s condition on the resultant machined surface integrity . Machinability and Surface Integrity condition degrade...

Ngày tải lên: 21/06/2014, 22:20