Machining of High Strength Steels With Emphasis on Surface Integrity by air force machinability data center 7 ppt

Machining of High Strength Steels With Emphasis on Surface Integrity by air force machinability data center_1 pot

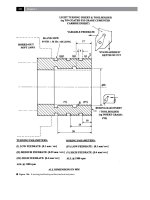

... G-code. Conversely, a ‘non-modal’ G-code will only aect the programmed block in which it appears. Machinability and Surface Integrity 7 Machinability and Surface Integrity ‘It is common sense ... commercial (PPT) testpiece has been developed showing typical machining data employed, based upon the secondary machining operations de- manded by many companies on...

Ngày tải lên: 21/06/2014, 22:20

Machining of High Strength Steels With Emphasis on Surface Integrity by air force machinability data center_2 docx

... technique in conjunction with a strictly controlled and limited ma- chining strategy – based upon some form of ‘orthogo- nal array’ , in combination with the strength (i.e >5% ‘F-ratio’) of parameters ... situation is that surface texture continuously degen- erates, and it is only the burnishing (i.e.‘ironing’) of the surface that ‘masks’ the temporary improvement in mac...

Ngày tải lên: 21/06/2014, 22:20

Machining of High Strength Steels With Emphasis on Surface Integrity by air force machinability data center_4 pot

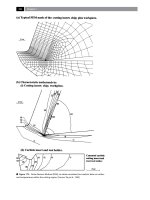

... at high feedrates when high- speed machining. Machinability and Surface Integrity Figure 1 57. A chatter model, with potential chatter conditions and the application of the ‘stability lobe ... result of energy Machinability and Surface Integrity dissipation – heat transformation, which could result in decreased tool life, with the superu- ous eect of therm...

Ngày tải lên: 21/06/2014, 22:20

Machining of High Strength Steels With Emphasis on Surface Integrity by air force machinability data center_5 pdf

... con- dition. Machinability and Surface Integrity Figure 163. Surface texture data- capture, with techniques for the derivation of the arithmetic roughness parameter: Ra. Machinability and Surface ... and position of the honing stroke, the hon- ing stick pressure (Vc). e inclination angle of the cross-hon- ing action, is a product of the up-/down-ward head motion (...

Ngày tải lên: 21/06/2014, 22:20

Machining of High Strength Steels With Emphasis on Surface Integrity by air force machinability data center_7 ppt

... ‘T’. NB is rate of heat generation only exists within the primary and secondary deformation zones. By way of example of how the temperature genera- tion/distribution occurs in orthogonal cutting, ... power of simulation – more will be mentioned on this subject later in the chapter. 7. 7 Tool Wear and Life Introduction e working environment for most machining pro- cesses i...

Ngày tải lên: 21/06/2014, 22:20

Machining of High Strength Steels With Emphasis on Surface Integrity by air force machinability data center_8 doc

... deformation – occurs when high pressures (i.e. compression) are exerted on the cutting edge in combination with elevated temperatures. Con- ditions likely to create plastic deformation on the ... of tool/workpiece anity associated with tem- Machinability and Surface Integrity • good quality and consistent workpiece material is to be utilised; • that the condition...

Ngày tải lên: 21/06/2014, 22:20

Machining of High Strength Steels With Emphasis on Surface Integrity by air force machinability data center_9 docx

... forming forces with very high- frequency acoustic emissions (AE). e application of AE in association with other Figure 177 . The correlation of typical manufacturing cost factors: machining ... application of the above equation for practical machining operations, due to the vast amount of machining data that is necessary to determine the parameters of this equation...

Ngày tải lên: 21/06/2014, 22:20

Machining of High Strength Steels With Emphasis on Surface Integrity by air force machinability data center_10 ppt

... thrust force component, • F C = cutting force component, • F N = normal force component on the shear plane, • F S = shear force component on shear plane, • R = resultant tool force component, • ... degree of con- sistency in the dialogue only one particular company’s FEA product will now be described. Computer Simulation of Machining Processes – an Introduction By...

Ngày tải lên: 21/06/2014, 22:20

Machining of High Strength Steels With Emphasis on Surface Integrity by air force machinability data center_11 pot

... 7. 10 Surface Integrity of Machined Components – Introduction Previously in Section 7. 5 concerning machined sur- face texture, the discussion was principally concerned with the resultant surface ... testing the surface topography. In Fig. 187b, an 11° sectional cut improves surface discrimination by increasing the vertical section magnication by around ve times. e...

Ngày tải lên: 21/06/2014, 22:20

Machining of High Strength Steels With Emphasis on Surface Integrity by air force machinability data center_12 pptx

... Figure 189. The inuence of the cutting edge’s condition on the resultant machined surface integrity . Machinability and Surface Integrity condition degrades the functional performance, due ... region extends to quite a small depth beneath the surface, in the region of 10 to 100 µm, de - pending upon the severity of the ‘abusive regime’ of surface generation. Con...

Ngày tải lên: 21/06/2014, 22:20