Cutting Tool Technology Industrial Handbook by Graham T Smith 2 pptx

Cutting Tool Technology Industrial Handbook by Graham T Smith_2 pptx

... combination of materials that constitute the cutter’s tool edge. Today, manufacturers of tooling have a strategy for continuous improvement with varia- tions in both tool matrices and coatings being ... stability of the workpiece -tool- machine set-up, other factors that could aect geometry selection include: whether con- tinuous, or intermittent cutting occurs, any tendency towar...

Ngày tải lên: 21/06/2014, 21:20

Cutting Tool Technology Industrial Handbook by Graham T Smith_4 potx

... factors, pos- sibly the most important one is that the swarf should ow smoothly away from the cutting area, as with the latest chip-breakers tted to today’s cutting inserts, chips can be readily ... Chip-breaking Technology consistent manner (3). It was found with this work- piece material in an experimental cutting proce- dure, that the tangential cutting force component,...

Ngày tải lên: 21/06/2014, 21:20

Cutting Tool Technology Industrial Handbook by Graham T Smith_5 pot

... aecting both the ma- chined surface texture and shortening tool life. Chip formation and its resultant morphology, is not only aected by the cutting data selected, but will be inuenced by the ... operations with the same tool, together with many other combined proled features. All of these opera- tions make signicant demands on the adaptability of the cutting insert’s geo...

Ngày tải lên: 21/06/2014, 21:20

Drilling and Associated Cutting Tool Technology Industrial Handbook_1 pdf

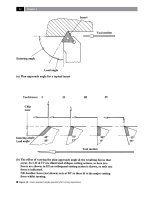

... conventional twist drill is depicted in Fig. 44a. From this illustration two dis- tinct cutting regions can be established: rstly, the main cutting edge, or lips; secondly at the intersection of the ... point and is produced by the line-of-contact, as the drill point initially touches the component’s surface, causing it to ‘walk’ until the feed/penetration stabilises itself at th...

Ngày tải lên: 21/06/2014, 21:20

Drilling and Associated Cutting Tool Technology Industrial Handbook_3 ppt

... generated are balanced, not with respect to the cut- ting edges – as is the situation with Twist drills – but invariably, by pads that are situated at 90° and 180° to that of the cutting edge. ... diameters – greater than 120 mm, • Limited machine tool power – alternatively, if it is not prudent to switch to another machine tool and/ or lose part orientation and register 24 , •...

Ngày tải lên: 21/06/2014, 21:20

Drilling and Associated Cutting Tool Technology Industrial Handbook_4 pot

... manufactured as solid one-piece tools, where the cutting edge was ground to the desired geometry by the skilled setter/operator, which meant that their useful life was to some extent restricted. ... ‘Qualied Tooling’ , refers to setting the tool s osets, with all the known dimensional data for that tool, allowing for ease of tool presetting and ecient tool- changing – more wi...

Ngày tải lên: 21/06/2014, 21:20

Drilling and Associated Cutting Tool Technology Industrial Handbook_5 potx

... are: • High temperatures in the cutting zone – necessitat- ing high temperature resistant and thermally-sta- bility of cutting insert materials, • Cutting force magnitudes are both higher and ... toolpost, allow- ing much greater tool rigidity and cutting stability, al- leviating many of the potential problematic in-service machining conditions. .. Multiple-Boring Tools Twin...

Ngày tải lên: 21/06/2014, 21:20

Drilling and Associated Cutting Tool Technology Industrial Handbook_6 pdf

... through the large automotive component, thereby supporting the machin- ing operation throughout its boring cycle, then retracting on completion, allowing the tool to be held in the machine tool s ... 52 Arithmetic roughness ‘Ra’ parameter – it is the arithmetic mean of the absolute ordinate values Z(x) within the sampling length. It is the most frequently quoted international surfac...

Ngày tải lên: 21/06/2014, 21:20

Drilling and Associated Cutting Tool Technology Industrial Handbook_7 docx

... calculated to the outer di- ametral dimension of the part feature to be machined. Solid post-drilling tooling can usually be operated at higher cutting data to that of their modular tooling counterparts. ... Experimental and Analytical Twist Drill Tempera- ture Distributions. Int. J. Mach. Tools Manufact., Vol. 30 (2) , 21 7 22 6, 1990. Anderson, P. Good points [Drilling geometries]....

Ngày tải lên: 21/06/2014, 21:20

Tài liệu Drugs and Poisons in Humans - A Handbook of Practical Analysis (Part 2) pptx

... sweat is a problem; it is di cult to collect it quantitatively. In actual cases, the sweat components are collected by wiping the skin surface with cotton, gauze or towel; PharmChek TM sweat ... droplets and cho- lesterol crystals. It begins to accumulate in the large intestine at week 16 of pregnancy, and is not excreted before birth; it is excreted 1–3 days a er birth [22 ]. Ostrea...

Ngày tải lên: 22/01/2014, 00:20

- oracle soa suite 11g handbook by lucas jellema pdf

- oracle soa suite 11g handbook by lucas jellema pdf free download

- data structures and algorithms in python by michael t goodrich

- rich dad poor dad by robert t kiyosaki pdf free download

- roll forming handbook by george halmos

- hvac systems design handbook by roger w haines

- practical electric motor handbook by irving gottlieb

- the oxford dictionary of english etymology by c t onions